Description

- The machine come with different options viz. manual control, logic control and micro processor control with computer interface.

- The inner basket, the outer drum end plates, safety guards and control panel are constructed using stainless steel.

- The reduction pulley system or gear box with pulley ensures a smooth and soft drive.

- Fully automatic panel box that is easy to operate.

- Hot forged end flange shafts long life.

- Unique design which consists of raising the door height above the center of the drum, increases liquor holding capacity, which leads to better loading ratios.

- Calibrated level indicator to control water level.

- Large cast-iron drainage ensures quick release of water and very low maintenance.

- Models include steam, electrical or thermal fluid heating mechanisms.

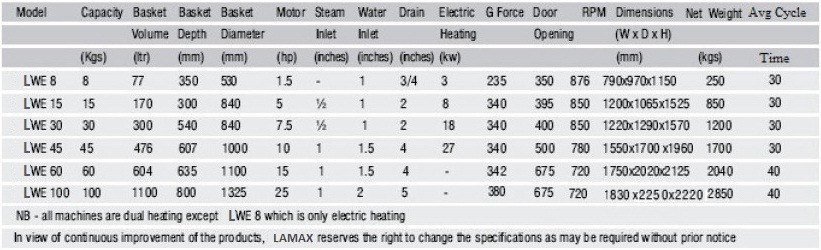

Specification

Description

- Micro processor control to offer different programs of wash cycles.

- This machine has an open-pocket cylinder and is self balancing

- The variable speed drive with high speed extraction is suitable for all kinds of washing and dyeing to obtain a worn or stone washed effect with enzyme treatment.

- A micro processor come standard with the machine which helps to control different programs of wash cycles.

- The cylinder beaters are specially designed to ensure a gentle, rapid and uniform treatment of all fabrics.

- This is an extremely versatile machine that can be used in the garmenting as well as commercial laundry industries.

- A whole range of washes including enzyme, stone wash, regular detergent wash to even garment Dyeing can be performed via this machine.

- The variable working and extraction speeds help perform the above washes.

Optional Features

- Tanks for additives with pump.

- Heat exchanger with pump

- Highly accurate liquor ratio electronic flow meter

- Colour mixer / salt dissolver with pump

Specification

Description

- Inner stainless steel basket with complete logic programmer with auto controls such as Auto reverse, Digital temperature indicator / controller, forward timer with pause timing and total time.

- The drive is through balanced closed grained cast ironed pulleys with matching V belts pedigreed bearings of NTN/similar are made to sustain radial and axial loads.

- The inner basket is double insulated with first quality mineral wool held in place by fine aluminum sheet backing on loaded spring hooked ties.

- The Inner stainless steel basket is a fitted with CNC designed stainless steel paddles to ensures smooth tumbling effect.

- High Load capacity ratings, self cleaning lint screen and other designed features make this drier a space and energy saver and guarantees faster drying time.

- As an option, dryers are also available in all stainless steel construction.

Specification

Dry Cleaning Machine

Specification

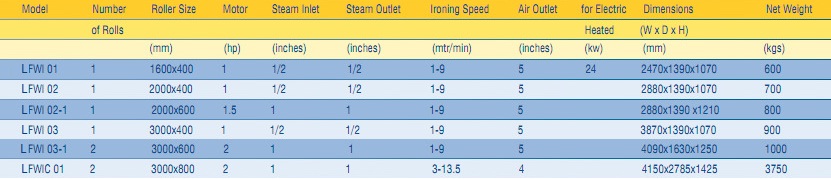

Flat Work Ironer

Description

- This is a unique machine to dry and iron all flat materials such as Bed Sheets, Pillow covers, Table Cloth & Napkins directly after Hydro extraction to produce a quality finish.

- Excellent design of roller angle ensures greater area of contact to give higher output and increased productivity.

- This machine is fed from the front, with a front return type. Micro processor control and inverter drives are present to regulate speed up to 10 mtrs/ min.

- Feeding and heating belts are imported to ensure the best quality and long life.

- Very low power and steam consumption compact design of front head and return requires working space only on the front side.

- This machine is equipped with digital temperature indicator and digital speed indicator.

- Hand safety guard and emergency stop are provided to ensure safe working conditions. Variable speed drive for different types of fabrics and reversing the direction are also possible.

- Specially designed blower to remove excess moisture.

- Available in 2 standard sizes.

- Machines of higher evaporation ratio with 600 mm also available.

Specification

Textile processing machine

Description

- This versatile machine has both the outer and inner drum made of tested stainless steel.

- The perforations in the inner basket are precision punched and embossed in a CNC machine.

- The machine is Stainless steel to AISI Grade 304 for wetted parts and side belt guards and other external parts.

- This machine is hydraulically operated for lifting and unloading and consists of 2 Nos. of 150 mm dia pneumatically operated drains & dual water inlet for hot & cold water.

- Heating is through steam with provision for both direct injection through a specially designed injector for efficient & noiseless mixing and also through an indirect heating thermal fluid jacket.

- The drive is through a reduction pulley belt drive for smooth and noiseless working.

- The basket is supported on heavy-duty self-alinging ball bearings.

Special Features

- Auto Tilting

- Variable Frequency Drive

- Auto PH Meter

- Automatic Chemical

- Dozing

- Flow Meter

- Auto Time and Auto Temperature Control

- LAN Connection on Actual Length of Cable etc.

Hydro Extractors

Lamax Direct Drive – LDD

Description

- The Inner basket and the outer drum are made of stainless steel; the inner basket is directly

- The motor is suspended with a coaxial setup along with thermal and anti humidity insulation.

- All the machines have the necessary door lock mechanism and continuous current braking system to assure a simple and safe operation.

- The design provides a quick, self-balancing, noiseless and vibration-less performance.

Lamax Non-Coaxial – LNC

Description

- Rugged close grained graded cast iron construction with pedigreed hydraulic transmission clutch to provide smooth and vibration free extraction on balanced loads.

- The drive from the hardened main steel spindle to the hydraulic clutch is through matched V-belts drive, with spring loaded friction, ferrado brake liners with tensioners to reduce high initial torque.

- The machine comes standard with control, electrical and safety limit switch on the loading door.

Lamax Heavy Duty – LHD

Description

- High capacity, efficient and energy consumption.

- Auto controlled devices, timer and balanced protection brake.

- Overload display device and cover protect device ensures safety operation and extends the life span of the machine.

- Additional load/unload features make the operation very convenient.